The principle of the compressed air filter of an air compressor: the compressed air passes through the filter element, and some solid particles are blocked by the filter element, so that the content of solid particles in the compressed air is reduced, and part of the water is concentrated and removed when it passes through the filter. The filter filters out impurities and oil in the gas to ensure the cleanliness of the incoming gas. The filter filters out solid dust and liquid moisture and oil droplets through the precise spatial network structure of the filter.

| Quantity: | |

|---|---|

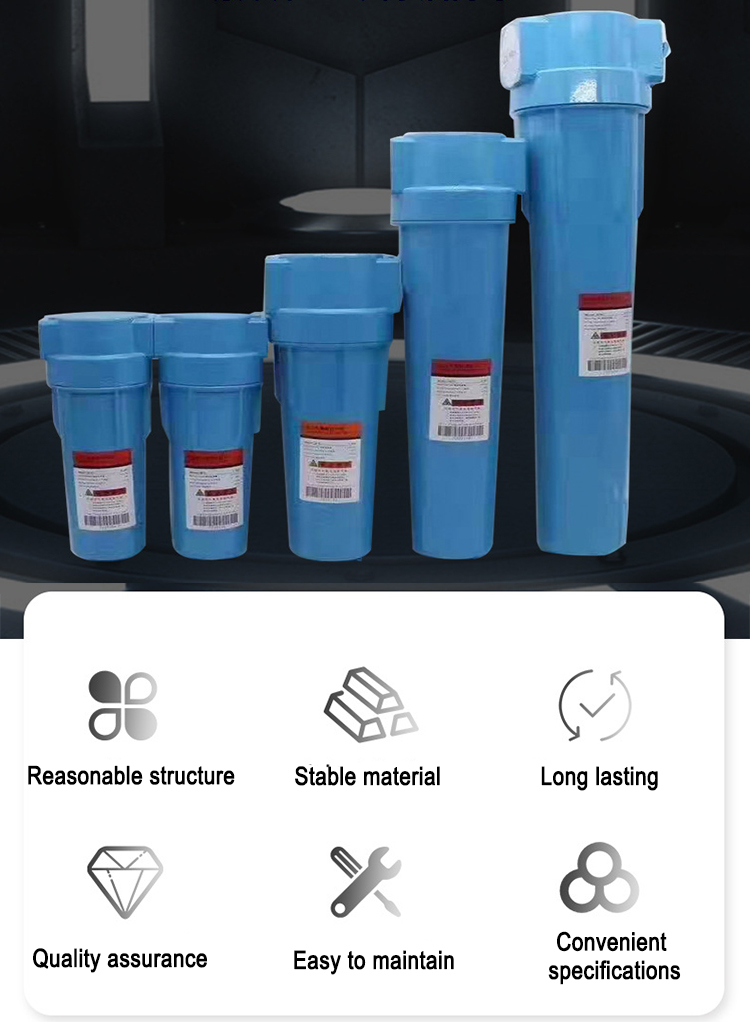

Precision Compressed Air Filter for Screw Air Compressor

The compressed air precision filter is used to remove contaminants in the compressed air system, such as dust, iron filings and dirt, corrosive solid particles, compressor lubricating oil, condensed water droplets and acid-cooled condensate, as well as oil and hydrocarbon vapors, etc. Provide high-quality compressed air for the compressor air system to meet application requirements.

The main components are filter element, filter housing, end cover, rack and so on.

The material of the filter is generally the same as the material of the connecting process pipeline. For different conditions of use, filters made of cast iron, carbon steel, low alloy steel or stainless steel can be selected.

How to choose the right filter?

1. Inlet and outlet size: In principle, the inlet and outlet size of the filter should not be smaller than the inlet size of the matching pump, and it is generally the same as the intersection of the inlet pipe.

2. Working pressure: Determine the pressure level of the filter according to the maximum pressure that may appear in the filter pipeline.

3. Filtration level: Mainly consider the size of the particles to be intercepted, depending on the process requirements of the medium flow rate. You can check the screen size of various sizes and check the screen size.

4. Air handling capacity: The large air handling capacity is based on the working pressure of 0.7-1.0Mpa.

5. Filter material: The filter material is generally the same as the material used to connect the process pipeline. For different use conditions, cast iron, carbon steel, low alloy steel or stainless steel filters can be considered.

Precision Compressed Air Filter for Screw Air Compressor

The compressed air precision filter is used to remove contaminants in the compressed air system, such as dust, iron filings and dirt, corrosive solid particles, compressor lubricating oil, condensed water droplets and acid-cooled condensate, as well as oil and hydrocarbon vapors, etc. Provide high-quality compressed air for the compressor air system to meet application requirements.

The main components are filter element, filter housing, end cover, rack and so on.

The material of the filter is generally the same as the material of the connecting process pipeline. For different conditions of use, filters made of cast iron, carbon steel, low alloy steel or stainless steel can be selected.

How to choose the right filter?

1. Inlet and outlet size: In principle, the inlet and outlet size of the filter should not be smaller than the inlet size of the matching pump, and it is generally the same as the intersection of the inlet pipe.

2. Working pressure: Determine the pressure level of the filter according to the maximum pressure that may appear in the filter pipeline.

3. Filtration level: Mainly consider the size of the particles to be intercepted, depending on the process requirements of the medium flow rate. You can check the screen size of various sizes and check the screen size.

4. Air handling capacity: The large air handling capacity is based on the working pressure of 0.7-1.0Mpa.

5. Filter material: The filter material is generally the same as the material used to connect the process pipeline. For different use conditions, cast iron, carbon steel, low alloy steel or stainless steel filters can be considered.