Key Components of Air Compressors and Maintenance Guide

Air compressors are vital tools used across industries like manufacturing, automotive, and construction. They power various machines and tools, making operations efficient. However, understanding their parts is essential for proper maintenance and troubleshooting.

In this post, you’ll learn about the key components of air compressors, their functions, and how they work together to keep your system running smoothly.

How Do Air Compressors Work?

Air compressors use a simple but effective process to compress air and store it for later use.

Basic Working Principles

- Air Intake: The compressor draws in ambient air through an intake valve.

- Compression: The air is then compressed, either by a reciprocating piston or rotating screws, depending on the type of compressor.

- Cooling: The compression process generates heat, so the air is often cooled before moving to the storage tank.

- Storage: The compressed air is stored in a tank until it’s needed.

- Regulation: As air is used, the compressor will kick on and off to maintain pressure within a set range.

Compression Process

Reciprocating Compressors

- The piston moves down, drawing air into the cylinder through an inlet valve.

- The piston then moves up, compressing the air.

- The compressed air is forced out through an exhaust valve into the storage tank.

Rotary Screw Compressors

- Air enters the compression chamber, where it’s trapped between two meshed helical screws (rotors).

- As the screws turn, the space between them decreases, compressing the air.

- The compressed air is then discharged into the storage tank.

In both types, an air filter cleans the incoming air, a check valve prevents backflow, safety valves protect against over-pressurization, and pressure switches control the motor based on tank pressure. Many compressors also include an oil pump and lubrication system. An air-oil separator removes oil from the compressed air before use. The compressor cycles on and off to maintain a steady supply of compressed air.

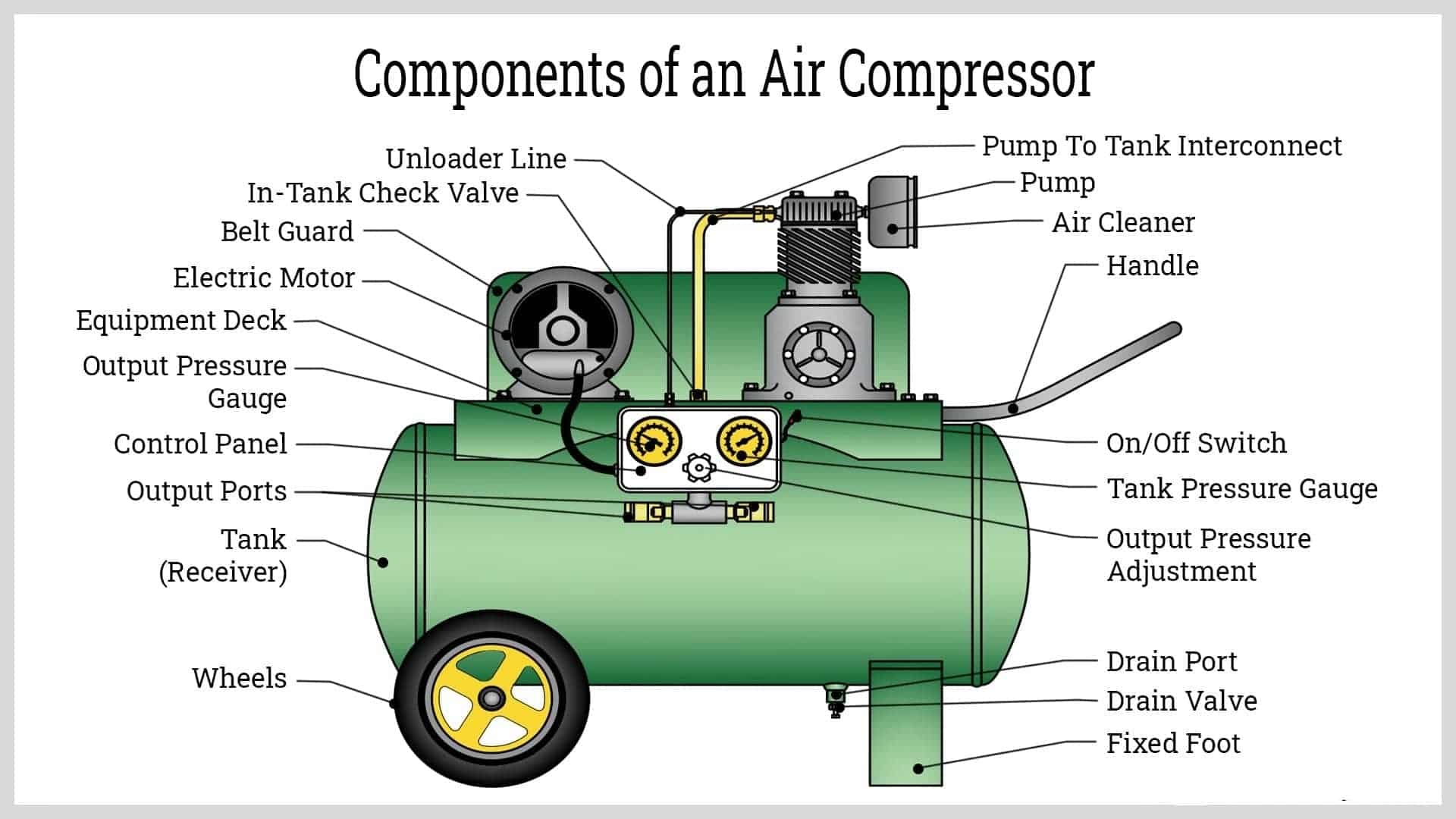

Core Components of an Air Compressor

| Component | Description |

|---|---|

| Motor | Provides mechanical energy to drive compression; electric (AC/DC) or gas-powered options. |

| Air End (Rotary Screw) | Pair of helical rotors compressing air; includes inlet valve, bearings, seals, discharge port, housing, internal cooling. |

| Pump (Reciprocating) | Piston-cylinder mechanism; includes cylinder, piston, inlet/exhaust valves, connecting rod, crankshaft; may be multi-stage for higher pressures. |

Understanding these core components helps with troubleshooting and maintenance tasks such as replacing seals or valves.

Essential Supporting Components

Oil Pump and Lubrication System

- Oil Filter: Removes impurities from the oil.

- Oil Cooler: Dissipates heat from the oil.

- Air-Oil Separator: Removes oil from compressed air.

- Oil Sump: Stores oil when not circulating.

- Oil Lines: Carry oil to moving parts.

Pressure Gauges

Monitor system pressure in PSI or bar; essential for safe and efficient operation.

Check Valve

Allows compressed air to flow from compressor to tank without backflow, maintaining consistent pressure.

Safety Pressure Relief Valve

Releases excess pressure if tank pressure exceeds set limits, preventing dangerous over-pressurization.

Unloader Valves

Release trapped air when the compressor starts, ensuring motor startup without fighting built-up pressure.

Pressure Switches

Monitor tank pressure and control motor on/off cycles to maintain pressure within set range.

Belts (Belt-Driven Compressors)

Transmit power from motor to pump or air end. Regular inspection and replacement prevent slippage and damage. Direct-drive models connect motor directly to pump, offering fewer maintenance points.

Air Filter

Prevents dust and contaminants from entering the compressor, prolonging component life and ensuring cleaner output air.

Drain Valves

Remove accumulated moisture and condensate from tank and lines. Manual or automatic drainage prevents corrosion and maintains air quality.

Gaskets

Seals between components to prevent air leaks. Regular checks and replacements maintain performance.

Vibration Pads

Reduce noise and wear by isolating vibrations, leading to quieter operation and longer component life.

Hoses and Connections

Carry compressed air from tank to tools or machinery. Choose appropriate length and diameter to avoid flow restrictions. Inspect regularly for kinks, leaks, or damage.

Maintenance Tips for Air Compressor Parts

Cleaning Air Compressor Filters

- Locate filter housing near air intake.

- Remove filter and tap gently to dislodge dirt.

- If very dirty, clean with compressed air or wash with soap and water; dry completely before reinstalling.

- Replace if damaged or excessively dirty.

Clean or replace filter every few months or more often in dusty environments.

Replacing Air Compressor Oil

- Run compressor briefly to warm oil, then turn off.

- Place pan under oil drain valve at pump base and drain oil completely.

- Close valve and refill with manufacturer-recommended oil to proper level.

Change oil every 500–1000 hours of use or every 3–6 months, depending on model and usage.

Signs Your Compressor Hose Needs Replacement

- Visible cracks or surface damage.

- Leaks detected by soapy water bubbles.

- Stiffness or brittleness indicating imminent failure.

Choose hoses rated for maximum pressure and flow. Replace damaged hoses promptly.

Testing and Replacing a Faulty Pressure Switch

- Unplug compressor and drain tank air.

- Locate pressure switch, remove cover, disconnect wires.

- Use a multimeter to test continuity: continuity at low pressure, no continuity at high pressure.

- If faulty, note wiring, install a new switch with same ratings, reconnect wires, adjust cut-in/cut-out settings per specifications.

Consult manual or a professional if unsure.

Common Problems and Troubleshooting Tips

Compressor Not Building Pressure

- Motor Issues: Overheating, low voltage, wrong extension cord gauge, faulty capacitor, or burnt-out motor.

- Pump Problems: Worn cylinder walls, leaking inlet/discharge valves, worn piston seals.

- Hose and Connector Issues: Leaks or loose fittings; inspect and replace or tighten as needed.

Air Leaks

- Worn Seals: Replace deteriorated seals in pump, valves, connections.

- Damaged Hoses: Inspect and replace cracked or holey hoses.

- Loose Connections: Tighten or replace loose fittings.

Noisy Compressor

- Motor Issues: Squealing from loose/worn drive belt; tighten or replace. Grinding from worn bearings; replace bearings. Capacitor faults causing hum; replace capacitor.

- Pump Problems: Knocking or rattling from worn pistons, cylinders, or bearings; replace as needed. Loose flywheel, pulley, or guards; tighten.

- Fan Issues: Rattling or clicking from loose/damaged fan; tighten or replace fan.

Conclusion

Understanding your air compressor’s parts is key to keeping it running smoothly. Familiarize yourself with your model’s specific components. Regular maintenance and prompt issue resolution ensure efficient, reliable operation. With this knowledge, you can keep your compressor in top shape for years to come.