Project Case Study: Chongqing Tunnel Construction with Aivyter Energy-Efficient Compressors

Project Overview

- Location: Chongqing, China

- Project Type: Tunnel Construction

- Previous Equipment: Traditional Two-Stage Screw Air Compressors

- Issues Identified:

- High energy consumption due to constant full-pressure operation (132KW motors)

- Frequent no-load or light-load operation resulting in significant energy waste

- Power grid instability affecting other equipment

- Excessive noise during operation

Aivyter Solution

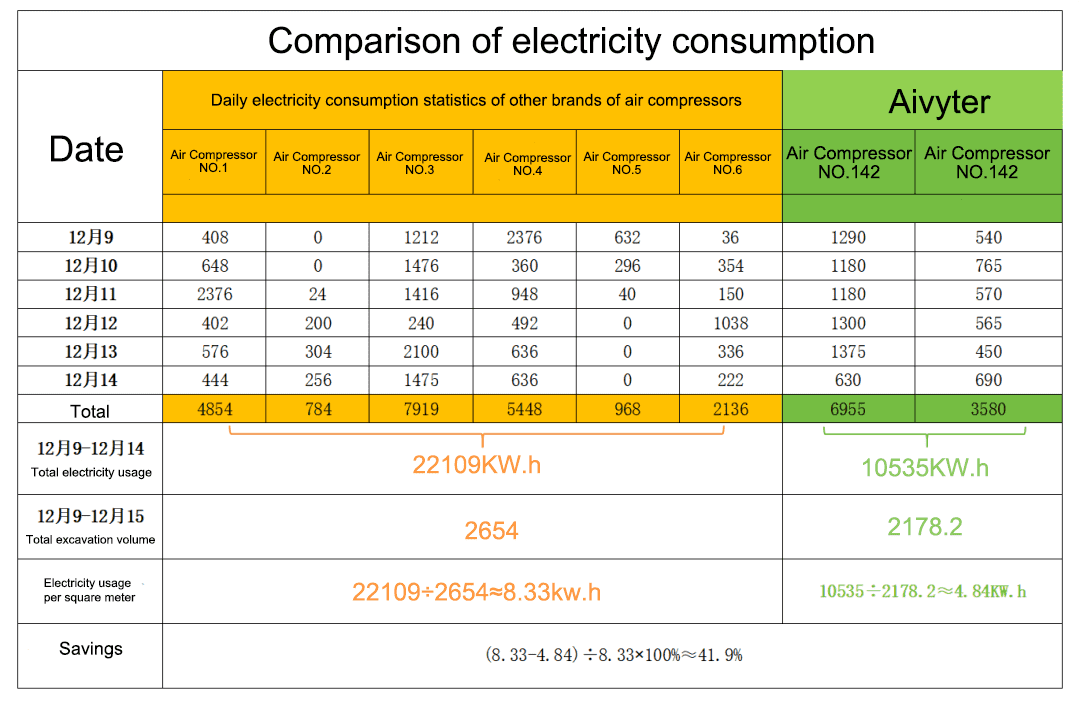

To resolve the above challenges, the project team deployed two Aivyter energy-efficient compressors to replace the outdated systems. A detailed comparison test was conducted by monitoring the excavation process in both the left and right tunnels.

Comparison Before and After the Upgrade

- Energy Savings: Approximately 41.9% reduction in power consumption over a 6-day period

- Efficiency Improvement: Saved about 3.5 kWh per cubic meter of excavated material

- Recognition: Project team praised the significant performance and environmental benefits

Long-Term Savings Potential

With every cubic meter saving 3.5 kWh, the energy cost reduction across your entire project could be massive. Whether your project involves 10,000 or 100,000+ m³ of excavation, the savings scale with volume—offering both economic and environmental benefits.

Why Choose Aivyter Energy-Efficient Compressors?

- ✅ Outstanding Energy Savings: Reduce energy use by nearly 42% compared to traditional compressors

- ✅ High Efficiency: Designed for optimal performance in both full and light load conditions

- ✅ Reliable Operation: Ensure safe and stable performance throughout tunnel excavation

- ✅ Environmentally Friendly: Support national goals for energy conservation and carbon reduction

Contact Us

Looking to transform your tunnel construction operations and cut energy costs?